NexSens T-Node FR Temperature Sensor User Guide

Real-Time Water Temperature Measurements

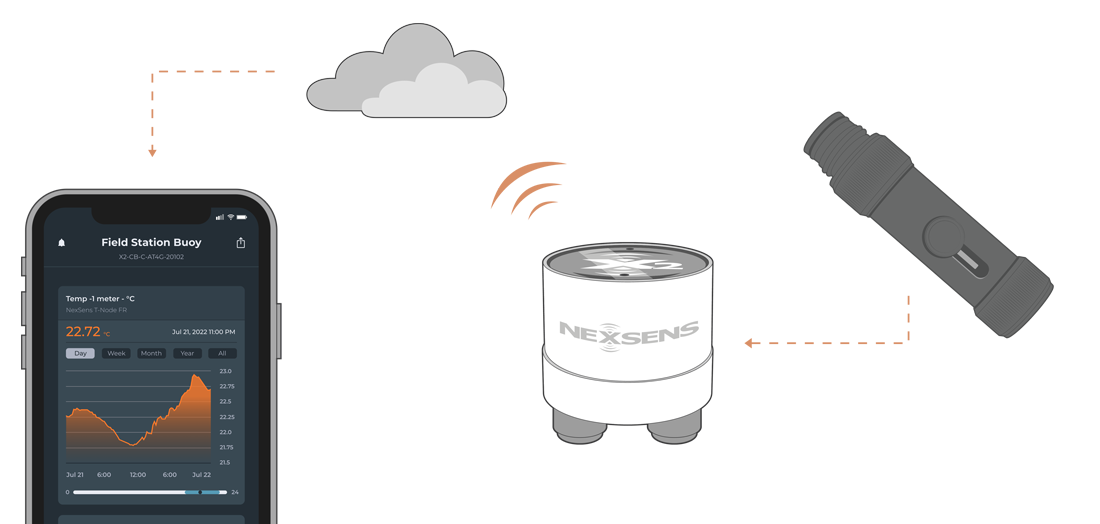

The NexSens T-Node FR water temperature sensor utilizes an integral titanium thermistor secured in a protective housing for underwater deployments in fresh, brackish or seawater. T-Node FR sensors integrate with NexSens X-Series data loggers using the Modbus communication protocol and RS-485 sensor interface. A pre-defined script on NexSens X-Series data loggers is available to detect, log and transmit the temperature data. Parameter data is transmitted, in real-time, at a user-specified interval (e.g., 10 minutes) to the NexSens WQData LIVE web data center. There, data is stored on customizable dashboards with available statistics, graphical interfaces, and the ability to download and send data reports via Email, FTP or an API. Below is information on the settings and wiring required to integrate these sensors with a NexSens X-Series data logger.

Figure 1: NexSens T-Node FR Temperature Sensor integration with NexSens X-Series data loggers for real-time water temperature measurements.

Compatible Models

NexSens T-Node FR sensors can be connected in series using UW underwater cables and suspended vertically in a water column or horizontally along a stream or riverbed. Double O-rings (both gland and face seals) ensure a reliable and watertight connection. These sensors offer pass-through signals for SDI-12 and RS-232, allowing the user to connect other environmental measurement sensors along the temperature string. This sensorBUS architecture has been designed so researchers can easily build and customize multi-point sensor strings and environmental monitoring networks. For connection to external data collection platforms, the T-Node FR sensor string can integrate directly with a 3rd party data collection platform via RS-485 Modbus RTU.

Specifications

| Sensor Information

|

*On a string with multiple nodes, the nodes will be addressed in increasing numerical order. Use extreme caution when changing the address of a node in a T-Node FR string to ensure that the nodes remain in numerical order and the same address is not assigned to more than one node simultaneously.

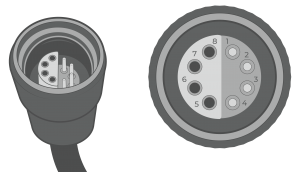

Third-Party Data Logger Integration

The NexSens UW-Receptacle to Flying Lead cable is an accessory that may be purchased separately for the integration of a T-Node FR string with a third-party data logger or SCADA system. NexSens X2-series data loggers have built-in UW-receptacle ports to accommodate a direct connection of the string. Follow the wiring table below and reference the T-Node FR/TS210 register information to gather readings from the temperature string.

| Receptacle Pin | Wire Color | T-Node FR Signal |

| 1 | Green | RS485A |

| 2 | Blue | RS485B |

| 3 | Brown | Pass-through |

| 4 | Red | 5-24V+ |

| 5 | White | — |

| 6 | Yellow | Pass-through |

| 7 | Black | GND |

| 8 | Orange | Pass-through |

Integration with NexSens X-Series Loggers

All T-Node FR/TS210 temperature strings must be addressed in increasing numerical order along the string. Modbus RTU allows the sensors to be addressed from 1 to 256. NexSens X-Series data loggers have a pre-defined script that will program the exact number of nodes on the string and gather temperature measurements at a user-specified interval.

1. Change the Modbus Address in iChart

A single T-Node FR sensor or T-Node FR/TS210 temperature string can be directly connected to a PC using a NexSens RS-485 UW Sensor USB Adapter. This adapter provides the ability to check sensor functionality or adjust the sensor’s Modbus address. Follow the article below to set the addresses for each T-Node FR/TS210 node on the string.

Change the Modbus Address of a T-Node FR

2. Pre-Deployment Check/Setup

It is recommended that field deployments be carefully planned and it is best to completely configure the system on a lab bench and test it for a period of time prior to taking it to the field. This will ensure a successful deployment and quality data collection. It is much easier to troubleshoot problems in the lab than in the field.

Connector Inspection

Whenever a string is assembled or re-connected, verify that the plug and receptacle O-rings of each sensor and UW-connector cable are present and in good condition. Additionally, verify that there are no signs of moisture or corrosion on any of the T-Node FR or UW-cable connectors (if re-deploying an old string).

TS-Clamp mooring line connection

Temperature strings are frequently attached to a mooring line to keep them fixed in place vertically within a water column. This technique helps to ensure that temperature data is consistently being monitored at the desired depths. With the temperature string laid out on a flat surface, secure each T-Node FR to the sensor mooring line using TS-Clamp sensor mooring clamps. The TS-Clamp accessory can be used to affix a T-Node FR thermistor string to a mooring line for deployment.

Cable Armoring

For any T-node FR deployment, apply cable armor to all portions of the sensor string that have the potential to wear against irregular surfaces.

3. Automatic Sensor Detection

After setting the node addresses in increasing numerical order and connecting them to the sensor mooring line, the temperature string can be programmed onto the logger via automatic detection.

X-Series Logger Detection and Script Information

The X-Series data loggers include a pre-loaded T-Node FR/TS210 script, which is enabled by default upon shipment. For new data loggers, connecting the string and providing power will force the logger to run through an automatic detection process.

For loggers with adjusted settings, use the link below to confirm the script is enabled before running a sensor detection.

| Logger Script Number | Sensor Interface | Baud Rate | Power Type | Warmup Period (sec) | Frame |

| 1000 | RS-485 | 19200 | Switch | 2 | 8N1 |

Read Sensor Configuration – Confirm Sensor Detection

After ~5-10 minutes, read the sensor configuration to confirm all nodes on the string and other connected sensors have been detected on the data logger. Thoroughly review the parameter list to ensure all parameters are accounted for and are measured in the desired units. Let the unit gather a few readings to confirm accurate and reasonable parameter data.

If a node is not detecting on a NexSens X-Series data logger after following the integration guide, below is a link outlining a few common reasons that should be reviewed.

Why is my temperature string not detecting?

4. Setting up WQData LIVE

Once an X-Series data logger has finished a new sensor detection, it will automatically push the sensor configuration to the WQData LIVE web data center. Follow the three articles below to create a WQData LIVE account, create a new WQData LIVE project and site and add the data logger to the project.

- Create a WQData LIVE Account

- Create a Project on WQData LIVE

- Add a Data Logger to a Project on WQData LIVE

Real-Time System Application

Real-time water temperature measurements from the NexSens T-Node FR temperature strings are useful in various environmental monitoring applications.

Applicable Systems

Discover applicable uses for the NexSens T-Node FR temperature string.

- HABs Detection Systems

- Inland Lake Monitoring Systems

- Large Lake Monitoring Systems

- Temperature Profiling Systems

Case Studies

Read about specific applications using NexSens T-Node FR temperature strings.

- Lake Temperature Profile

- Washington Reservoir Temperature Changes

- Great Pond Changing Water Quality

- Buffalo Pound Lake Algae Blooms

Water Temperature Measurements

Learn more about water temperature measurements on the NexSens Blog Page.