In-Situ AquaTroll X-Series Integration Guide

Real-Time Water Quality Measurements

The In-Situ Series of Multi-Parameter Water Quality Sondes (AquaTroll 200/400/500/600) are compatible with NexSens X-Series data loggers using the Modbus-RTU communication protocol and RS-485 sensor interface. A pre-defined script on X-Series data loggers is able to detect, log and transmit all parameters available on all models of In-Situ sondes. Parameter data is transmitted, in real-time, at a user-specified interval (e.g., 10 minutes) to the NexSens WQData LIVE Web Datacenter. There, data is stored on customizable dashboards with statistics and graphical interfaces for each parameter. Users can download and send data reports via Email, FTP, or an API. Below is information on the settings and wiring required to integrate these sensors with a NexSens X-Series data logger.

Figure 1: In-Situ AquaTroll Multi-Parameter Water Quality Sonde integration with NexSens X-Series data loggers.

Compatible Models

In-Situ offers four sonde models that are compatible with NexSens X-Series data loggers – the AquaTroll 200, 400, 500 and 600. By adjusting only a few settings using the In-Situ Modbus Sensor Communication Device Kit or the NexSens UW-USB-485R-DC, the sensor can be ready for integration. The internal script on X-Series data loggers will automatically detect the probes connected to the sonde and the corresponding parameters that they measure.

Figure 2: In-Situ AquaTroll 200 Multi-Parameter Water Quality Sonde

|  Figure 3: In-Situ AquaTroll 400 Multi-Parameter Water Quality Sonde

|

Figure 4: In-Situ AquaTroll 500 Multi-Parameter Water Quality Sonde |  Figure 5: In-Situ AquaTroll 600 Multi-Parameter Water Quality Sonde |

In-Situ Sonde Integration

All In-Situ Sondes integrated at NexSens will require either a receptacle to flying lead cable to interface with the sensor using the In-Situ Modbus Sensor Communication Device Kit or the NexSens UW-USB-485R-DC. The communication cables allow the user to adjust internal settings and calibrate the sensor as necessary.

1. Wiring for Software Communication

AquaTroll Water Quality Sondes can be configured using the Win-Situ 5 software and communication device kit provided by In-Situ. If the sensor has a NexSens UW8 plug connection, a UW-FLxR can connect to the In-Situ communication kit following the wiring table below.

| Communication Kit Color Indicator | Signal | NexSens UW-FLxR Wire Color |

| Blue | RS-485 A (+) | Green |

| Green | RS-485 B (-) | Blue |

| Black | Ground | Black |

| Red | Power | Red |

2. Configure Communication Settings

- Connect the USB cable to a PC that contains the latest version of the Win-Situ 5 software.

- Open the Win-Situ 5 software.

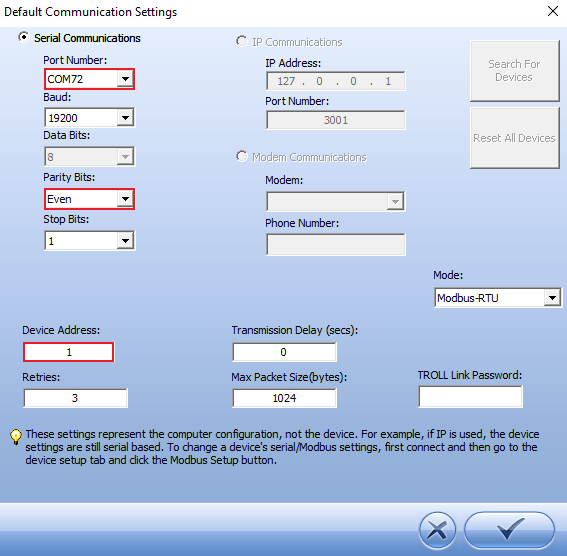

- Go to Preferences | Comm Settings to insert the correct COM port and address for the sensor for the initial connection.

- Brand new sensors should have address 1 and Even parity.

- Click the checkmark at the bottom once the proper changes are made.

Figure 6: Default communication settings for initial connection.

- Go to File | Connect to connect to the device.

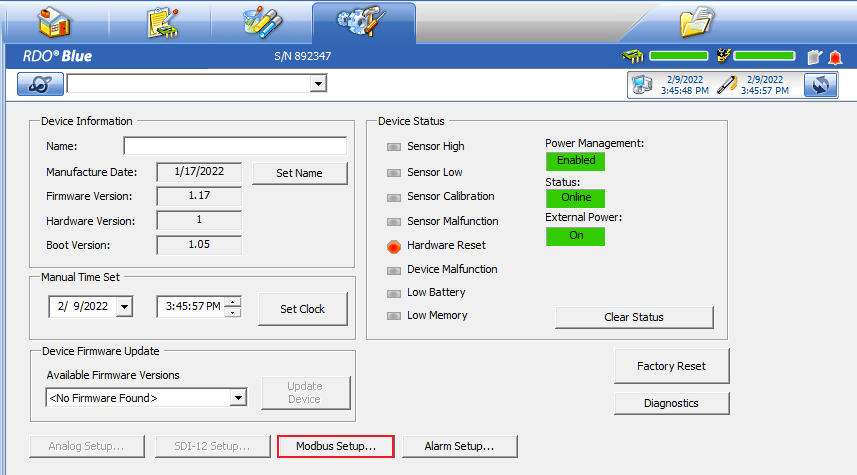

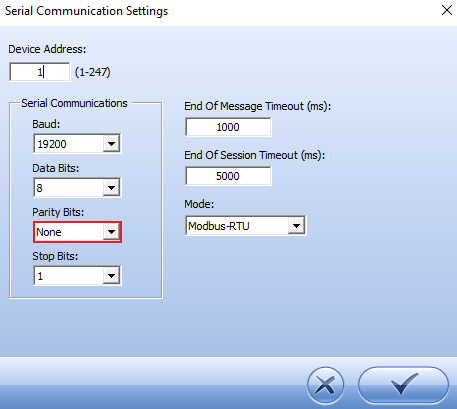

- Travel to the tools icon once connected to the device and click on the Modbus Setup. Change the parity (and address if it interferes with other sensors) to None.

- It is recommended to change the SDI-12 address to ensure there is no interference with other SDI-12 sensors.

Figure 7: Modbus settings setup.

Figure 8: Change parity to none.

- Now that the communication settings have changed, the software will disconnect from the sensor unless changes to the default settings are made.

- The sensor is now ready for detection on the X2 data logger.

3. Automatic Sensor Detection

After adjusting the internal communication settings, the sensors and their parameters can be programmed onto the logger via automatic detection.

X-Series Script Information

The X-Series data logger includes a pre-loaded AquaTroll script, which is enabled by default upon shipment. For new data loggers, connecting the sensor and providing power will force the data logger to run through an automatic detection process.

For loggers with adjusted settings, use the link below to confirm the In-Situ script is enabled before running a sensor detection.

| Logger Script Number | Communication Protocol | Baud Rate | Power Type | Warmup Period (sec) | Frame |

| 1004 | Modbus | 19200 | Switch | 2 | N81 |

AquaTroll Parameters

The AquaTroll 200 & 400 have the following pre-defined parameter lists for the internal 1004 script.

AquaTroll 200

| Parameter | Default Unit |

| Pressure | PSI |

| Temperature | °C |

| Level | Feet |

| Specific Conductivity | uS/cm |

| Salinity | ppt (parts per thousand) |

| Total dissolved solids | ppt (g/L on WQData LIVE) |

AquaTroll 400

| Parameter | Default Unit |

| Dissolved Oxygen | mg/L |

| Temperature | °C |

| Dissolved Oxygen | % |

| Specific Conductivity | µS/cm |

| Salinity | ppt (parts per thousand) |

| Total dissolved solids | ppt (parts per thousand; g/L on WQData LIVE) |

| Pressure | PSI |

| Level | Feet |

| pH | — |

| pH | mV |

| ORP | mV |

The parameters for the AquaTroll 500 and 600 sensors are dependent on the probes connected to the sonde. Below are the available probes and their corresponding parameters.

AquaTroll 500/600

| Probe | Parameters | Default Units |

| Temperature | Temperature | °C |

| Conductivity | Temperature | °C |

| Conductivity | µS/cm | |

| Specific Conductivity | µS/cm | |

| Salinity | ppt (parts per thousand) | |

| Total Dissolved Solids | ppt (parts per thousand) | |

| Resistivity | Ohm-cm | |

| Density of Water | g/cm3 | |

| Dissolved Oxygen | Dissolved Oxygen Concentration | mg/L |

| Dissolved Oxygen Saturation | % saturation | |

| pH | pH | — |

| pH | mV | |

| ORP | mV | |

| Turbidity | Turbidity | NTU |

| Total Suspended Solids* | mg/L | |

| Barometric Pressure | Barometric Pressure | mmHg |

| External Voltage | V | |

| Level | Pressure | PSI |

| Depth | ft. | |

| Chlorophyll-a | Chlorophyll-a Intensity | RFU |

| Chlorophyll-a Concentration** | µg/L | |

| Blue Green Algae – Phycocyanin | BGA-PC Intensity | RFU |

| BGA-PC Concentration | µg/L | |

| Blue Green Algae – Phycoerythrin | BGA-PE Intensity | RFU |

| BGA-PE Concentration | µg/L | |

| Nitrate ISE | Nitrate Concentration | mg/L |

| Nitrate | mV | |

| Ammonium ISE | Ammonium Concentration | mg/L |

| Ammonium | mV | |

| Chloride ISE | Chloride Concentration | mg/L |

| Chloride | mV |

*Total Suspended Solids from Turbidity Tech Note

**Chlorophyll-a is programmed to report in RFU and can be configured to display Chl-a concentration; however, the user must first program in a conversion factor. To obtain the conversion factor, the user must obtain a grab sample of water at the deployment location and record the RFU reading from the sensor at the same time. Then, perform lab extraction of Chlorophyll-a (per APHA standard method 10200-H) to determine the µg/L. The laboratory-obtained concentration in mg/L divided by the RFU reading of the same water will give the conversion factor. It is best to do this with several water samples from the same location and then average the conversion factors calculated to get better accuracy.

Read Sensor Configuration – Confirm Sensor Detection

After ~5-10 minutes, read the sensor configuration to confirm the sensors have been detected on the data logger. Thoroughly review the parameter list to ensure all parameters are accounted for and are measured in the desired units. Let the unit gather a few readings to confirm accurate and reasonable parameter data. Review the Troubleshooting section if the sonde does not appear in the logger programming.

If an In-Situ sensor is not detecting on a NexSens X-Series data logger after following the integration guide, below is a link outlining a few common reasons that should be reviewed.

Why is an In-Situ Sensor Not Detecting?

4. Setting up WQData LIVE

Once an X-Series data logger has finished a new sensor detection, it will automatically push the sensor configuration to the WQData LIVE Web Datacenter. Follow the three articles below to create a WQData LIVE account and a project/site. Then add the data logger to the project using the included claim code.

- Create a WQData LIVE Account

- Create a Project on WQData LIVE

- Add a Data Logger to a Project on WQData LIVE

Real-Time System Application

Real-time water quality measurements from the In-Situ Series of Multi-Parameter Water Quality Sondes are useful in various environmental monitoring applications.

Applicable Systems

Discover applicable uses for the In-Situ AquaTroll Water Quality Sondes.

- Acid Mine Runoff Monitoring Systems

- Turbidity Monitoring Systems

- Dissolved Oxygen Monitoring Systems

- HABs Detection Systems

- Inland Lake Monitoring Systems

- Large Lake Monitoring Systems

- Source Water Monitoring Systems

- Stream and River Monitoring Systems

Case Studies

Read about specific applications using In-Situ AquaTroll Water Quality Sondes.

Water Quality Measurements

Learn more about water quality measurements on the NexSens Blog Page.

- Water Quality Sensor Options

- Nutrient Monitoring – Nitrate

- Source Water Monitoring – Raw Water Intake

- Turbidity Monitoring at Dredge Sites