X2 Logger Diagnostic Readings

All X2 data loggers have an internal set of sensors that measure important system health factors, which are called meta parameters or diagnostic readings. The X2 collects a total of (12) X2 meta parameters/diagnostic readings.

X2 Meta Parameter Descriptions

- Processor Power – The regulated supply power being fed to the X2’s CPU and other internal components. It is nominally 3.3V but typically ranges between 3.0-3.5V.

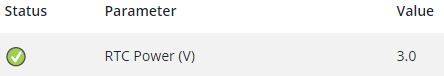

- RTC Power – A real-time clock (RTC) lithium coin battery inside each X2 allows the logger to maintain accurate time while powered down or reset. Values of 2.4V-3.3V are acceptable.

Values that fall below 2.4V indicate the battery is beginning to deplete. When reaching a critical level, the battery will no longer accurately keep time. When this occurs, the X2 clock will reset to Jan 1st 1970 at 12am (unix timestamp zero) each time following system reboot. To avoid data logging interruptions, it is recommended an X2 be sent to NexSens Technology to replace the RTC battery when it falls to 2.4V or below.

- Primary Power – Each X2 is capable of utilizing two independent power inputs for redundancy. Power provided in the following instances will be registered as Primary Power:

- Land-based X2 data loggers utilizing an SP-Series solar power pack or UW6-PW AC power adapter.

- Buoy-mounted X2-CB systems utilizing the solar charged batteries in the data well.

- X2-SDL data loggers accepting power from an SBP500 battery pack (or other external source) via the central 6-pin port on its bottom bulkhead.

Depending on the power source*, the following values are typical:

- 12V-15V for SP-Series solar power pack or CB-Series buoys.

- Consistent 12.1-12.5V for an AC power adapter.

- 8.5V to 12.9V for an SBP500 battery pack, depending on how recently the installed D-cell batteries were replaced.

*If none of these supplies are connected and a secondary power source is used, primary power will consequently read ~0V.

- Secondary Power – The X2 registers any power supplied through the secondary pins on a UW-6 plug connector as Secondary Power.

Typically, only X2-SDL systems running on internal D-cell batteries utilize the Secondary power input. All other systems will return ~0V (as shown), indicating that no secondary power input is present.

Note: Newer versions of X2 data loggers (manufactured after 2022) will have primary and secondary power connected; thus, all systems will have nearly identical primary and secondary power values.

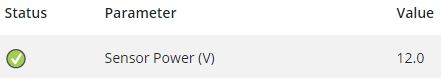

- Sensor Power – The X2 regulates power to its sensor ports. Depending on the state of the system’s primary or secondary power, the X2 will boost or reduce sensor power accordingly to maintain a nominal 12V output. In practice, these values tend to range from 11.8V-12.2V.Note: Newer versions of X2 data loggers (manufactured after 2022) do not regulate the power to the sensor ports. Thus, the sensor power and primary power will have nearly identical values.

- Total System Current – The X2 monitors the total power consumption of the electronics in the system (i.e. sum of the data logger and external sensors).

It is best to disregard the status icon designation for this parameter. Depending on the system setup (telemetry type, number of sensors, sensor types, etc.) and other system conditions (e.g. power supply voltage), a ‘normal’ current draw will vary widely between systems. Instead, use this to establish a baseline and investigate system health if any significant changes occur.

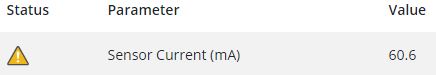

- Sensor Current – The current draw, at 12V, of all external sensors and devices connected to an X2 logger.

Similarly to total current, disregard the status icon and use historical data to establish a baseline range for the system’s sensor current.

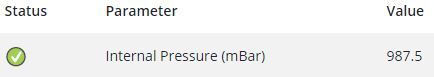

- Internal Pressure* – Reports the air pressure inside an X2 data logger housing. Useful for identifying when vent obstructions or excessive outgassing from charging system batteries occur.

* Note that X2 systems delivered any time after mid-2018 will not have an internal pressure sensor due to a parts shortage-induced design change. Dashes will occupy the value field as a result.

- Internal Temperature – Registers the ambient temperature inside the housing of the X2 logger.

- Internal Humidity – Reflects the amount of moisture in the air inside the X2 housing.

Acceptable values will range from a slight negative percentage (effectively zero) up to ~50%. If a logger reports humidity greater than 50%, replace the desiccant bag inside the X2 or X2-CB and inspect the enclosure seal. High humidity can contribute to telemetry problems and, in more extreme cases, damage the logger circuitry as a result.

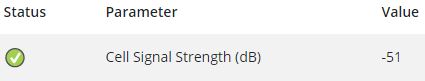

- Cell Signal Strength – Despite the name, cell signal strength is representative of the transmission signal strength for all telemetry-enabled X2s including radio and Iridium satellite.

Expected values are given in the following:

- Cellular systems

- -51 to -79 dBm for strong signal strength (~4-5 bars equivalent)

- -80 to -89 dBm for moderate signal strength (2-3 bars equivalent)

- -90 to -99 dBm for weak signal strength (1-2 bar equivalent)

- At -100 dBm or lower, connections will be intermittent at best

- Cellular systems

- Iridium satellite systems

- The value reflects the number of Iridium satellites the system can currently see

- 5 is the maximum corresponding with the strongest possible signal

- 0 is the lowest value, and connections typically fail at this level

- Iridium satellite systems

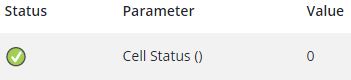

- Cell Status – The cell status field displays error codes from a failed or compromised X2 data transmission attempt. Similarly to cell signal strength, the cell status parameter applies to all telemetry types including cellular, radio, Iridium satellite, and Wi-Fi. Values of zero indicate that no errors were observed.

If status errors appear frequently and subsequently affect data transmissions, contact NexSens Technology for troubleshooting assistance. Supply the status error code reported by the logger.