Geolux Non-Contact Flow Sensor X-Series Integration Guide

Real-Time Water Velocity and Flow Measurements

The Geolux Non-Contact Flow Sensor measures water velocity and calculates overall flow in streams, rivers, and other water bodies. The sensors are compatible with the NexSens X-Series data loggers using the SDI-12 sensor interface and communication protocol. Parameter data is transmitted, in real-time, at a user-specified interval (e.g., 10 minutes) to the NexSens WQData LIVE Web Datacenter. There, data is stored on customizable dashboards with statistics and graphical interfaces for each parameter. Users can download and send data reports via Email, FTP, or an API. Below is information on the settings and wiring required to integrate Geolux Non-Contact Flow Sensors with NexSens X-Series data loggers.

Compatible Model

The Geolux Non-contact Flow Sensor has an integrated radar surface velocity and level sensor for contactless velocity, level, and discharge (flow) measurements. Calculation of the total flow discharge is internally implemented within the instrument by combining surface velocity measurement, water level measurement, and a configured cross-section of the river or channel. Defining the measurement parameters such as profile cross-section, material of the edges, location of the sensor above the water, and all other instrument settings can be set with the Geolux configuration application using any available communication interface.

Geolux Integration

Geolux sensors do not require a change in settings to communicate with an X-Series data logger. The default SDI-12 address of 1 is compatible. A thorough review of the deployment site must be conducted to determine the cross-sectional area of the channel. Along with the cross-sectional area, the sensor location in relation to the bottom of the channel is also necessary. All of these settings will be entered into the Geolux configuration application for more accurate level and flow readings. Follow the manual below to learn more about setting adjustments in the Geolux software:

Geolux Non-Contact Flow Sensor Manual

1. Wiring

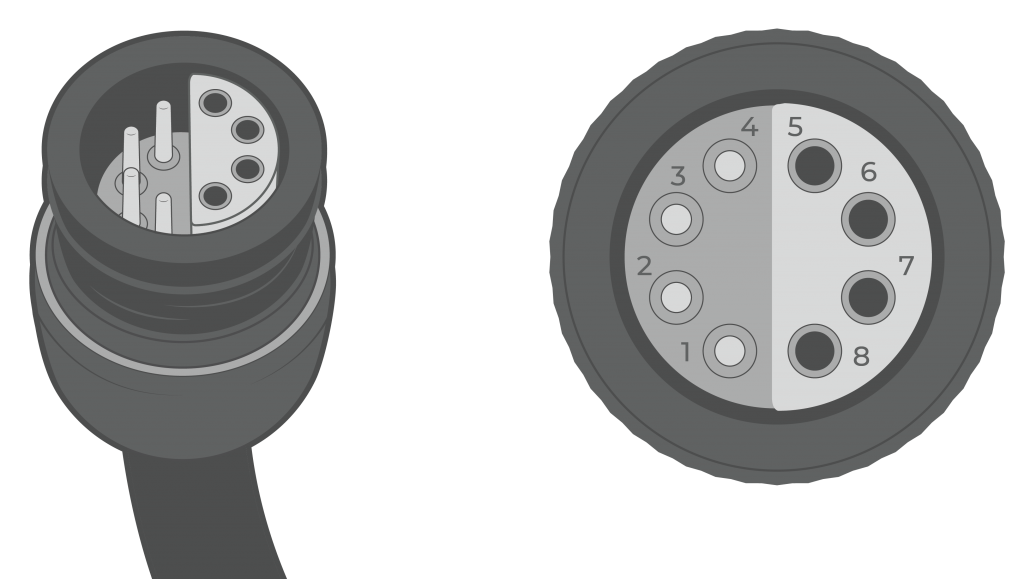

In nearly all applications involving NexSens integration, a connectorized UW8 plug will be added to the sensor cable. However, other applications may require a UW8 to flying lead cable utilized for wiring the sensor and cable into an external junction box. The following table provides information for both applications.

| NexSens UW8 Plug Pin | NexSens UW8-FLx Wire Color* | Signal | Geolux Cable Wire Color |

| 1 | Orange | RS-232 Tx | Yellow** |

| 2 | Black | Ground | Gray/White |

| 3 | Yellow | RS-232 Rx | Green** |

| 5 | Red | 12V Power | Brown |

| 6 | Brown | SDI-12 | Red |

| 7 | Blue | RS-485 B | Orange** |

| 8 | Green | RS-485 A | Dark Red** |

*NexSens UW Plug to Flying Lead Cable

**For communication in Geolux software

Figure 3: NexSens UW8 Plug pin numbers.

2. Automatic Sensor Detection

The user must create a Generic SDI-12 script through the NexSens CONNECT software to communicate and gather measurements from the sensor. The user must reference the SDI-12 address and parameters output by the sensor for proper configuration. Follow the link below to review the process for creating a Generic SDI-12 script through the CONNECT Software:

SDI-12 Script Generation

The Generic manufacturer and SDI-12 model must be selected in the SDI-12 script utility. The measurement command should always be ‘C’, which allows for measurements to be obtained concurrently with other SDI-12 sensors connected to the logger. Switch power provides a balance between power consumption and data accuracy. SDI-12 sensors require a specific warmup time depending on the number of parameters to be measured. Refer to the Geolux manual to set the appropriate warmup time.

| Manufacturer | Model | SDI-12 Address | Port | Warmup | Measurement Command | Power |

| Generic | SDI-12 | 0-9 (Default = 1) | P0, P1, or P2 | 30 seconds (Recommended) | C | Switch |

Parameter List from C Command

The default parameter list for the Geolux sensor is below. Match the parameter output below in the script.

| CONNECT Parameter Name | Units | Geolux Parameter Name |

| Flow | L/s | Discharge |

| Velocity | mm/s | Average Velocity |

| SNR | dB | Average SNR |

| Tilt | Deg | Tilt Angle |

| Generic | — | Signal Quality |

| Level | mm | Average Level |

| Depth | mm | Distance to Water’s Surface |

| SNR | dB | Level SNR |

| Generic | — | Standard Deviation of Water Level |

| Temperature | °C | Internal Device Temperature |

| Tilt X | Deg | Measured Tilt Angle in X Direction |

| Tilt Y | Deg | Measured Tilt Angle in Y Direction |

Run the Sensor Detection

Once the script is created, transfer and enable it on the data logger.

After the script is enabled, run a sensor detection to program the sensor onto the logger.

Read Sensor Configuration – Confirm Sensor Detection

After ~5-10 minutes, read the sensor configuration to confirm the sensors have been detected on the data logger. Thoroughly review the parameter list to ensure all parameters are accounted for and are measured in the desired units. Let the unit gather a few readings to confirm accurate and reasonable parameter data.

3. Setting up WQData LIVE

Once an X-Series data logger has finished a new sensor detection, it will automatically push the sensor configuration to the WQData LIVE web data center. Follow the three articles below to create a WQData LIVE account and a project/site. Then add the data logger to the project using the included claim code.

- Create a WQData LIVE Account

- Create a Project on WQData LIVE

- Add a Data Logger to a Project on WQData LIVE

Real-Time System Application

Real-time water velocity and flow measurements from the Geolux Non-Contact Flow Sensor are useful in various environmental monitoring applications.

Applicable Systems

Discover applicable uses for the Geolux Non-Contact Flow Sensor.

Case Studies

Read about specific applications using the Geolux Non-Contact Flow Sensor.

Sensor Manual

For additional information on the Geolux Non-Contact Flow Sensor, please refer to the Geolux Non-Contact Flow Sensor Manual.