Mooring Data Buoys

This article contains only general information on the available mooring options for NexSens data buoys. Developing an effective mooring strategy requires reviewing various application-specific criteria (water level fluctuations, currents and wave action, debris loads, etc.) before deployment. This document is intended to provide a starting place for mooring design and is by no means comprehensive. Good mooring design is often developed through years of experience with various deployment scenarios. For first-time mooring designers, it is best to include an experienced marine engineer.

NexSens Technology supplies mooring hardware to support user-designed systems but does not endorse any particular mooring strategy for any specific application and does not take responsibility for mooring performance or damage resulting from mooring failure.

Buoy Ballast

Buoy ballast is best handled by adding weight to the bottom of the buoy and not relying on the mooring weight to act as ballast. Additionally, the weight associated with biofouling growth can impact the buoy buoyancy and mooring performance. Minimum recommended ballast weights for NexSens Technology data buoys can be reviewed at the link below.

NexSens Technology Buoy Ballast Weights

More information on buoy ballast can also be found at the link below.

CB-Series Data Buoy Ballast Weight & Stability

Mooring Eye Lifting

All NexSens CB-Series buoy models have three topside mooring eyes located around the solar tower. These are sufficiently strong that a buoy can be lifted from a single top-facing eye nut via crane or winch for removal or deployment when required. Care should always be taken to avoid damaging any solar panels, topside sensor mounts and sensors connected to the instrument cage when lifting and moving a buoy.

Data Buoy Mooring Types

There are three commonly used mooring types for data buoy applications:

- Catenary moorings

- Semi-taut two point moorings

- Inverse-catenary (S-shape) moorings

1. Catenary Moorings

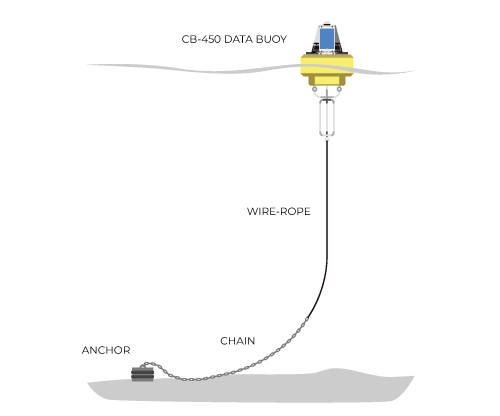

For shallow deployments with minimal wind, wave and current loading, most data buoys utilize catenary moorings. Shallow deployments can be designed with all chain or a combination of heavy bottom chain and light water column chain. Deeper water moorings may need to use a combination of chain and rope.

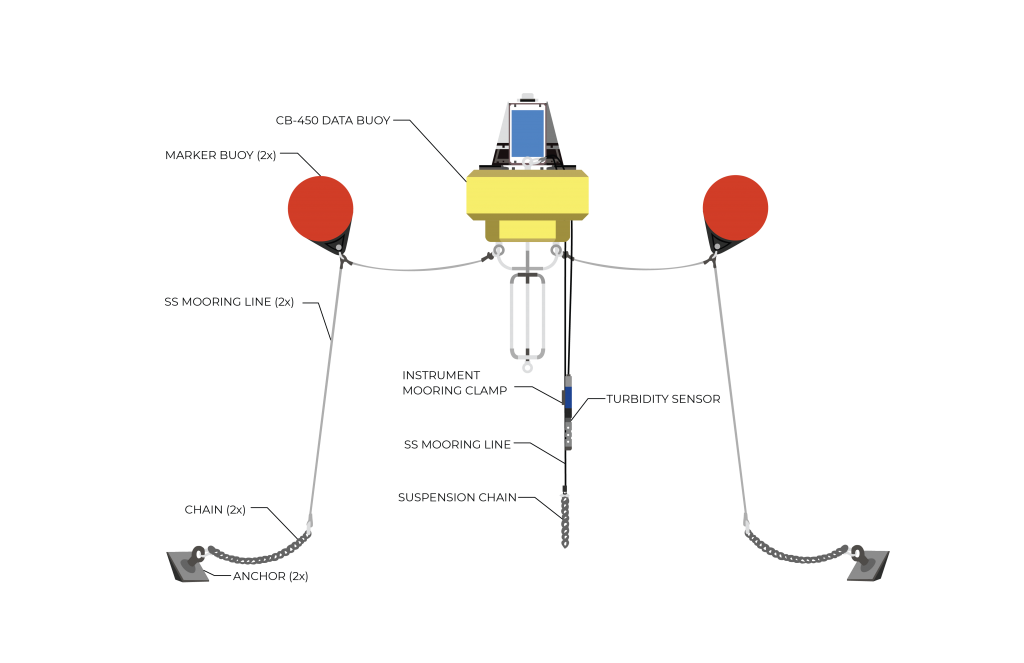

Figure 1: Example catenary mooring deployment with single chain for shallow waters. |  Figure 2: Example catenary mooring with combination of rope and chain for deeper waters. |

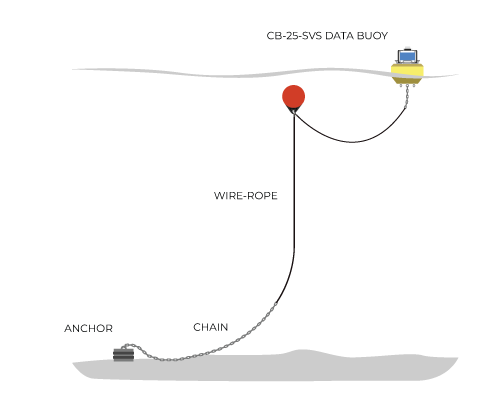

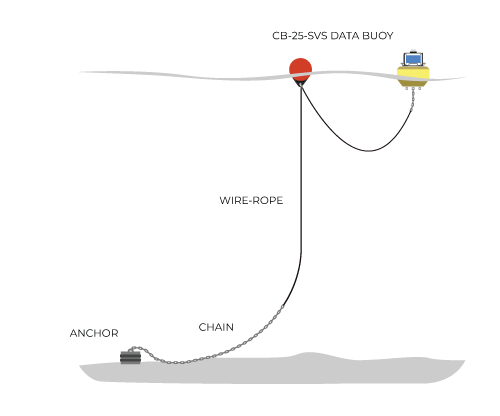

Small-buoy catenary moorings

Additional surface or subsurface floatation may be required for smaller buoyancy buoy applications where the floatation may not be adequate to support the mooring weight. Extra floatation can also free motion for wave measurement applications or offer additional resistance to horizontal loading.

Figure 3: Example small-buoy catenary mooring with subsurface flotation. |  Figure 4: Example small-buoy catenary mooring with surface flotation. |

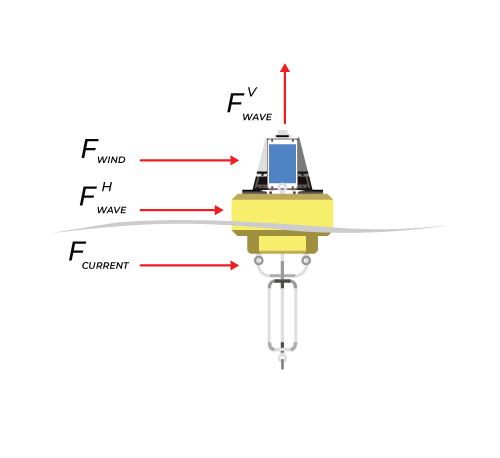

Horizontal Loading

As wind, wave and current loads increase, the buoy is driven away from the anchor and mooring can be pulled taut resulting in the buoy listing to one side. Damage can result with topside equipment and solar panels becoming submerged. Additional surface or subsurface floatation may be required.

Figure 5: Depiction of horizontal loading resulting in buoy listing to one side. |  Figure 6: Force diagram representing external forces acting on buoys in natural environments. |

2. Semi-taut two point moorings

For calm, shallow water with limited horizontal loading, semi-taut two point moorings can be utilized. These moorings are useful for suspending sensor lines by pulling the mooring lines free and clear. Rough water, shifting bottom or horizontal loads can tangle two point moorings and lead to chafing and cable failure. Use this mooring type only in controlled and calm applications.

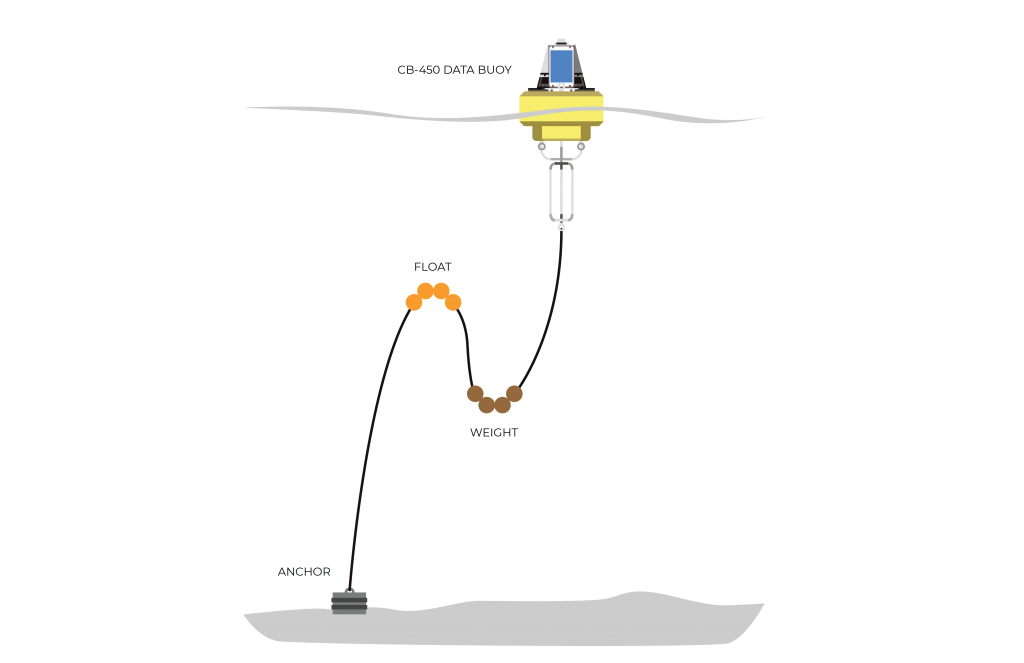

3. Inverse-catenary (S-shape) moorings

Inverse-catenary moorings are often referred to as S-shaped moorings. Floats and weights on the mooring lines create an S-shape, which provides spring action in the water column. Waves and water level changes are easily managed. This mooring type is most common on deep water deployments but has utility in shallow rough water applications.

Figure 8: Inverse catenary (S-shaped) mooring diagram.