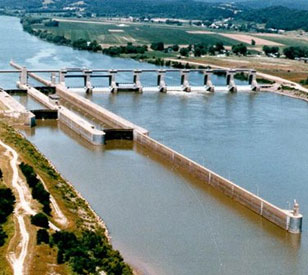

Located on the east bank of the Ohio River in Belleville, West Virginia at the US Army Corps of Engineers’ Belleville Locks and Dam, Belleville Hydroelectric is a municipality-owned, non-profit power plant.

Located on the east bank of the Ohio River in Belleville, West Virginia at the US Army Corps of Engineers’ Belleville Locks and Dam, Belleville Hydroelectric is a municipality-owned, non-profit power plant.

Hydroelectric plants provide a clean and renewable source of energy, without emitting any standard atmospheric pollutants or contributing to global warming. Hydropower is the primary contributor of renewable energy in the United States and can be produced as long as rain falls and rivers flow. These plants also provide water management, flood control, and recreational benefits.

While the benefits of hydroelectric plants certainly outweigh the costs, their construction can be disruptive to surrounding aquatic ecosystems. Dissolved oxygen content of the water may change from pre-construction conditions. Water exiting from turbines is typically much colder than the pre-dam water, which can change aquatic faunal populations.

The Federal Energy Regulatory Commission, or FERC, is an independent agency that licenses and inspects private, municipal, and state hydroelectric projects. NexSens Technology was selected to install and maintain real-time DO monitoring systems so plant personnel can monitor levels of dissolved oxygen upstream and downstream of the plant. This helps ensure that the plant meets FERC regulations.

Reliable Dissolved Oxygen Measurement Upstream and Downstream

NexSens Technology has maintained the DO monitoring systems since 1999, and engineers later installed a real-time radio telemetry system. Servicing of the DO monitoring system is generally performed on a scheduled monthly to bi-monthly basis. The summer months require more frequent visits due to algae and mussel growth on the dissolved oxygen sensor.

NexSens Technology has maintained the DO monitoring systems since 1999, and engineers later installed a real-time radio telemetry system. Servicing of the DO monitoring system is generally performed on a scheduled monthly to bi-monthly basis. The summer months require more frequent visits due to algae and mussel growth on the dissolved oxygen sensor.

YSI optical dissolved oxygen sensors provide cost-effective, reliable oxygen measurements at the hydroelectric dam. Optical technology improves performance and reduces maintenance, while integrated thermistors measure river temperatures. The sensor stores calibration data internally to simplify maintenance during routine site visits.

The radio telemetry system sends logged dissolved oxygen data to a plant server, which pushes it up to the NexSens WQData LIVE web datacenter. WQData LIVE allows Belleville Hydroelectric personnel to quickly generate data analysis reports. The reports show the difference in temperature and oxygen levels before and after the dam for regulatory compliance. An additional sensor at the dam tailrace provides a more complete overview. An annual report is submitted to the US Army Corps of Engineers.

By installing the real-time radio telemetry system and streaming data from the dam site to WQData LIVE, NexSens engineers can also remotely monitor the DO readings. This helps to quickly detect changes or drift possibly caused by unnatural means like sensor error or clogged deployment pipes. NexSens schedules additional service visits as needed to minimize system downtime.

Belleville Hydroelectric Plant Quick Facts

Original dam construction: 1963-1974

Hydroelectric plant construction: Completed 1999

Rated capacity: 42 MW

Power recipients: 42 member communities

Top image: Courtesy of American Municipal Power

The NexSens X2 Environmental Data Logger offers the latest in real-time monitoring technology with wireless communication, large plug-and-play sensor library, and ultra-low power consumption.

The MAST is a 2″ NPT aluminum pipe assembly for mounting an X2 data logger and SP-Series solar power pack.

The YSI EXO3s is a compact, batteryless sonde for monitoring major water quality parameters, including: pH, conductivity, temperature, turbidity and dissolved oxygen.

WQData LIVE is a web-based project management service that allows users 24/7 instant access to data collected from remote telemetry systems.