The Southern Illinois Power Cooperative operates a power plant near Lake of Egypt around the clock to produce energy for its customers. All the activity can stress the plant’s infrastructure, so key to continuing its operations is minimizing that stress as much as possible.

The Southern Illinois Power Cooperative operates a power plant near Lake of Egypt around the clock to produce energy for its customers. All the activity can stress the plant’s infrastructure, so key to continuing its operations is minimizing that stress as much as possible.

One of the main issues that plant managers encounter in overseeing operations is keeping equipment from overheating. They routinely pump in water from the lake to cool generators and ensure reliable power generation in the long term. Through being used as a cooling agent, the water is heated up considerably, and then must be condensed and cooled before it can be discharged back into the reservoir.

From that point in the process, plant managers monitor conditions in the reservoir to make sure that water plant discharge is cool enough to not impact water temperatures. Their concern is that overheated water could upset the ecosystem balance and hurt aquatic life and they work to put the water back in close to the temperature of the surrounding water.

To monitor the reservoir’s water conditions in real time and manage plant discharge, operators at the plant have deployed a data buoy. The buoy is equipped with temperature sensors and telemetry to let engineers know when conditions change so that they can adjust plant operations accordingly. The buoy is an improvement over methods used to track the temperatures in the past, which relied on temperature readings at the discharge point and then equations to estimate them at various points through the lake.

Monitoring plant discharge water

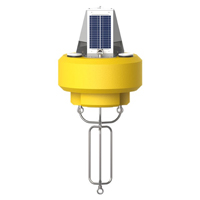

Real-time temperature monitoring is made possible by a NexSens CB-450 Data Buoy, which houses and supports all the devices necessary for the project. The CB-450 buoy was the ideal choice for the plant discharge application because of its design that stands up to deployments in inland lakes and reservoirs. It integrates an instrument well to hold data loggers, and batteries if needed, as well as passthrough holes to safely deploy sensors.

Real-time temperature monitoring is made possible by a NexSens CB-450 Data Buoy, which houses and supports all the devices necessary for the project. The CB-450 buoy was the ideal choice for the plant discharge application because of its design that stands up to deployments in inland lakes and reservoirs. It integrates an instrument well to hold data loggers, and batteries if needed, as well as passthrough holes to safely deploy sensors.

On top of the buoy is a Garmin GPS 19x HVS High Sensitivity Receiver that allows managers at the plant to keep tabs on its location at all times. Next to this is a solar marine light that acts as a beacon to warn boaters of the monitoring platform’s location.

Beneath the buoy and deployed securely in one of its passthrough holes is a NexSens TS210 Thermistor String that captures the reservoir’s temperature changes in a profile. Gathering that data through the water column is important because it shows managers how temperatures vary in different strata of the reservoir.

The GPS unit and the NexSens thermistor string both connect to an X2-CB Buoy Data Logger held securely in the buoy’s instrument well. The data logger is configured to communicate via radio telemetry and broadcasts sensor readings every 10 minutes to operations managers at the plant who view them on a computer running NexSens iChart software.

With real-time water temperature data, plant operations continue smoothly while the health of aquatic life in Lake of Egypt is protected. In addition, the data ensure that plant discharge operations are in line with recently added permit requirements from the U.S. EPA’s National Pollutant Discharge Elimination System.

The NexSens CB-450 Data Buoy is designed for deployment in lakes, rivers, coastal waters, harbors, estuaries and other freshwater or marine environments.

The X2-CB is a fully featured data logger housed inside a waterproof enclosure specifically designed to integrate with NexSens’ CB-Series data buoys.

The NexSens TS210 Thermistor String provides high precision temperature measurements for profiling in lakes, streams, and coastal waters.

The highly accurate GPS 19x HVS position receiver/antenna provides up to 10 Hz update rates for position, velocity and time data.