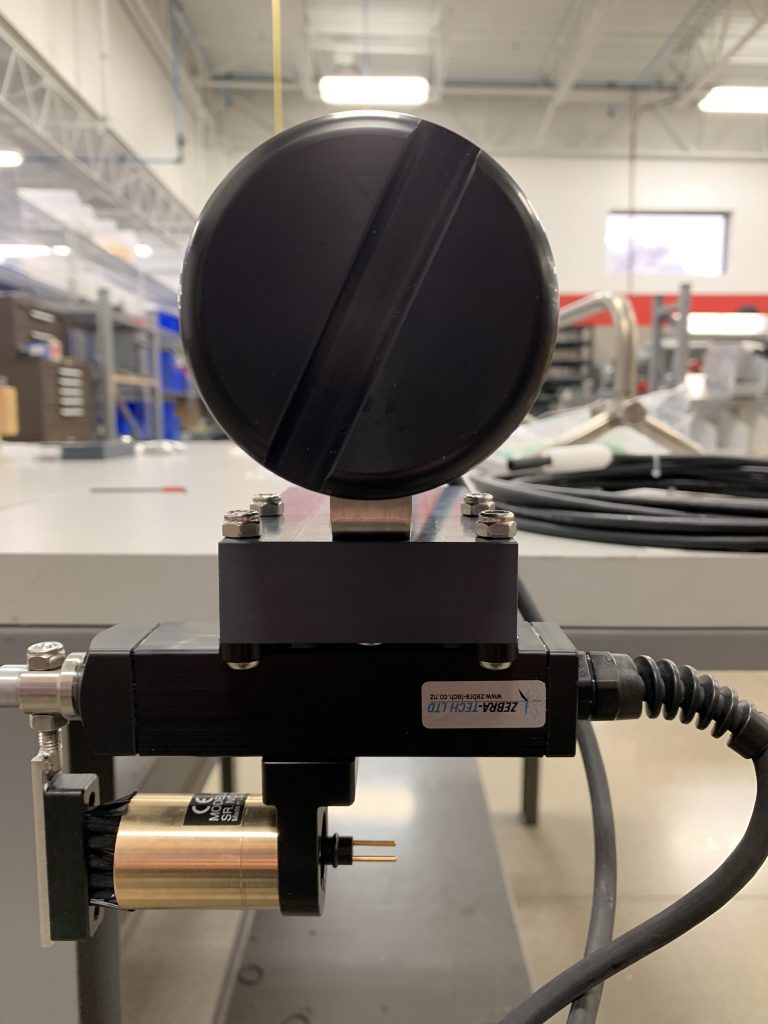

This article demonstrates how to mount a LI-COR 192 PAR sensor onto a Unistrut arm for small and large instrument cages.

Required Tools

Socket/combination wrench sets: 3/8″, 7/16″, 9/16″

Size 25 metric Allen wrench

Flat head screwdriver

Phillips head screwdriver

Included Components

- All Cage Sizes

- Mounting Block

- HydroWiper to Mounting Block– (7) 10-32x 1-3/8 pan head bolt, (3) #10 flat washer, (7) 10-32 Nylon insert nut

- Mounting Block to Unistrut Arm– (2) 3/8-16x 1-5/8 hex cap bolt, (2) 3/8 flat washer, (2) 3/8 fender washer

- For Standard Cage Only

- Unistrut Arm to Instrument Cage– (2) 1/4-20x 1″ ID U-bolt, (4) 1/4-20 Nylon insert nut

- For Large Cage Only

- Unistrut Arm to XL Instrument Cage– (2) 3/8-16x 1-1/4″ hex cap bolt, (4) 3/8 fender washer, (2) 3/8-16 Nylon insert locknut

Attach the Hydro-wiper to the mounting block

- Use a 3/8″ wrench and a Phillips-head screw driver to attach the Hydro-wiper battery pack to the mounting block with (3) 10-32 X 1-3/8″ pan head screws, (3) #10 flat washers, and (3) 10-32″ nylon insert locknuts from the “Hydro-Wiper to Mounting Block” bag.

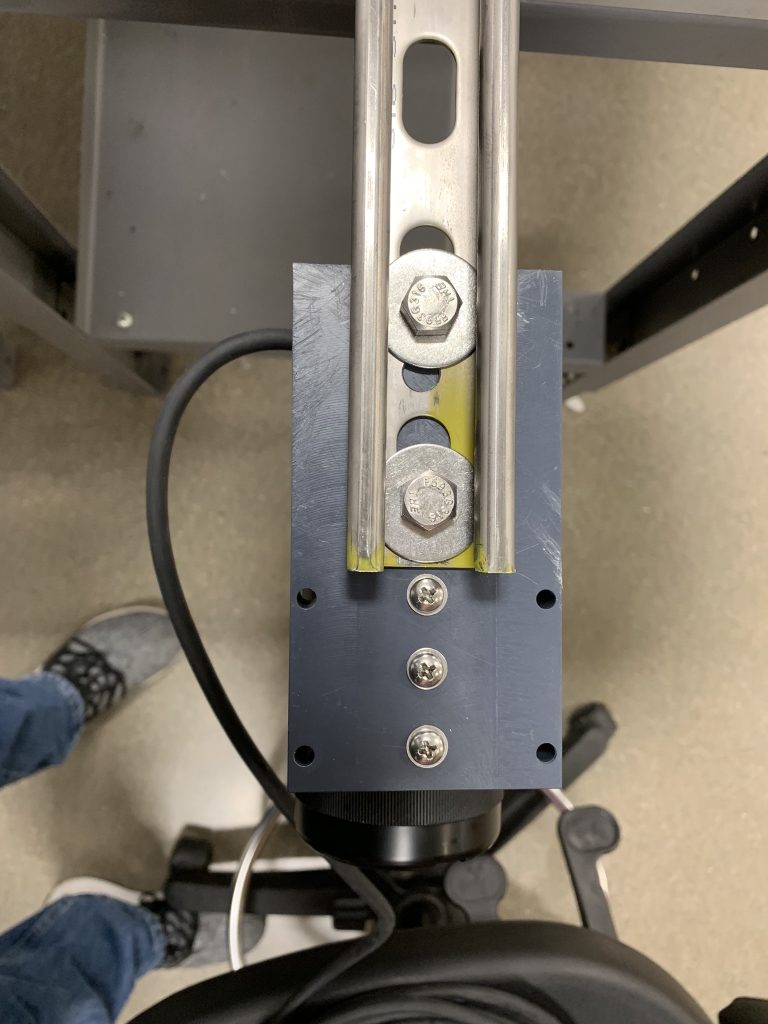

Attach the mounting block to the Unistrut arm

- Use a 9/16″ socket wrench and 9/16″ combination wrench to attach the mounting block to the Unistrut arm using the (2) 3/8-16 X 1-5/8″ hex cap bolts, (2) 3/8″ flat washers, (2) 3/8″ fender washers, and (2) 3/8-16″ nylon insert locknuts found in the “Mounting Block to Unistrut Arm” bag .

- Slide the fender washers into the Unistrut arm and align them with the 2 large holes on the mounting block.

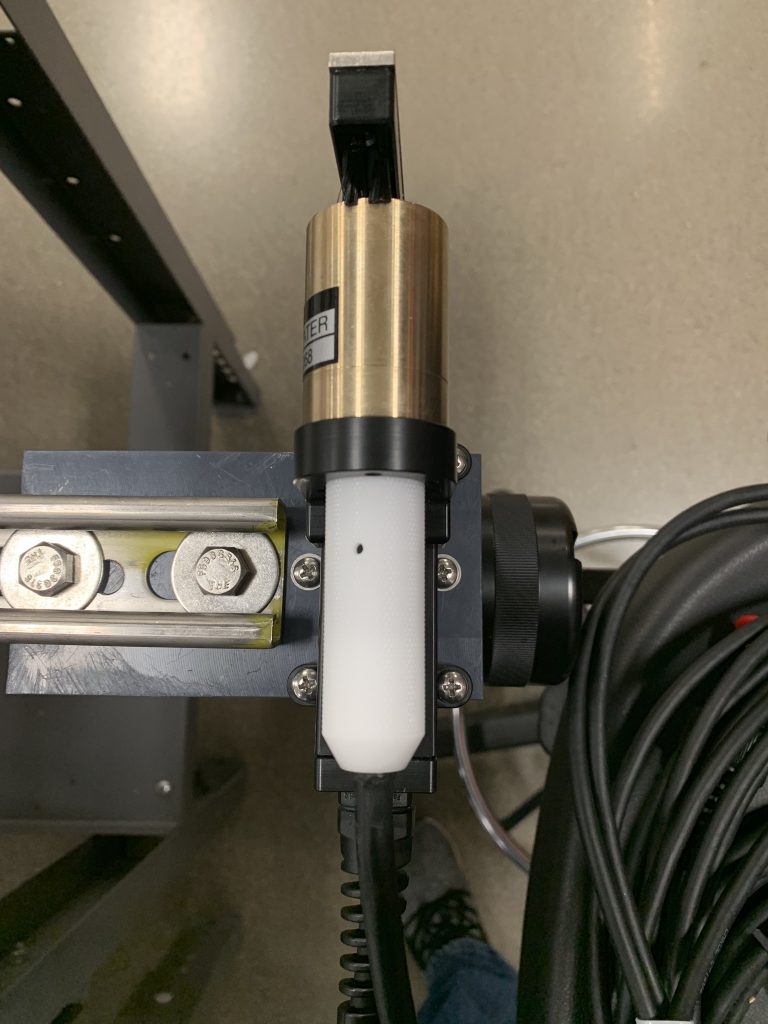

Attach the LI-COR 192 sensor to the Hydro-wiper

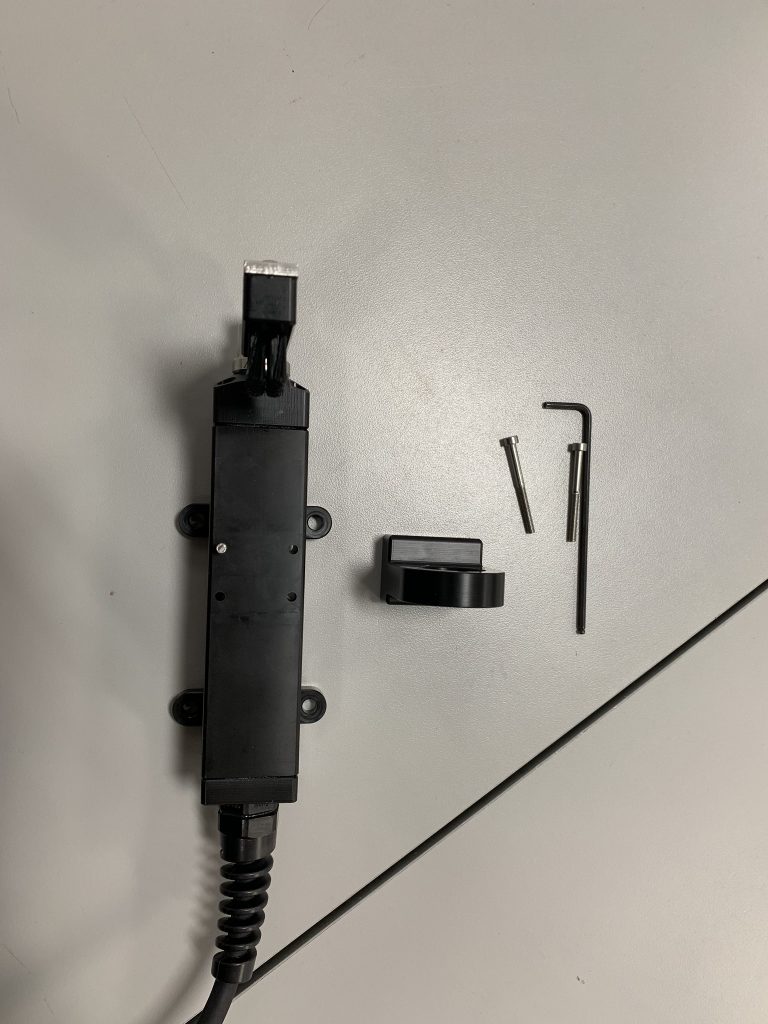

1. Use a size 25 metric Allen wrench to remove the sensor holder from the Hydro-wiper.

2. Locate the yellow marking on one of the edges of the Li-192’s black collar. Note this location relative to the sensor label prior to placing it inside the HydroWiper holder. This will be necessary for proper cable orientation later.

3. Remove the protective red polymer cap from the face of the Li-192 and reattach the sensor holder assembly to the HydroWiper using a 25mm Allen key.

4. Use a flat head screwdriver to insert the (3) 6-32 X 3/4″ mounting screws provided by LI-COR into the bottom of the sensor holder.

a. Note that the screws were not fully tightened during documentation to maintain the integrity of the shrink tubing on the screws.

Attach the hydro-wiper to the mounting block

- Use a 3/8″ wrench and a phillips-head screw driver to attach the Hydro-wiper to the mounting block with the remaining (4) 10-32 X 1-3/8″ pan head screws and (4) 10-32″ nylon insert locknuts from the “Hydro-Wiper to Mounting Block” bag.

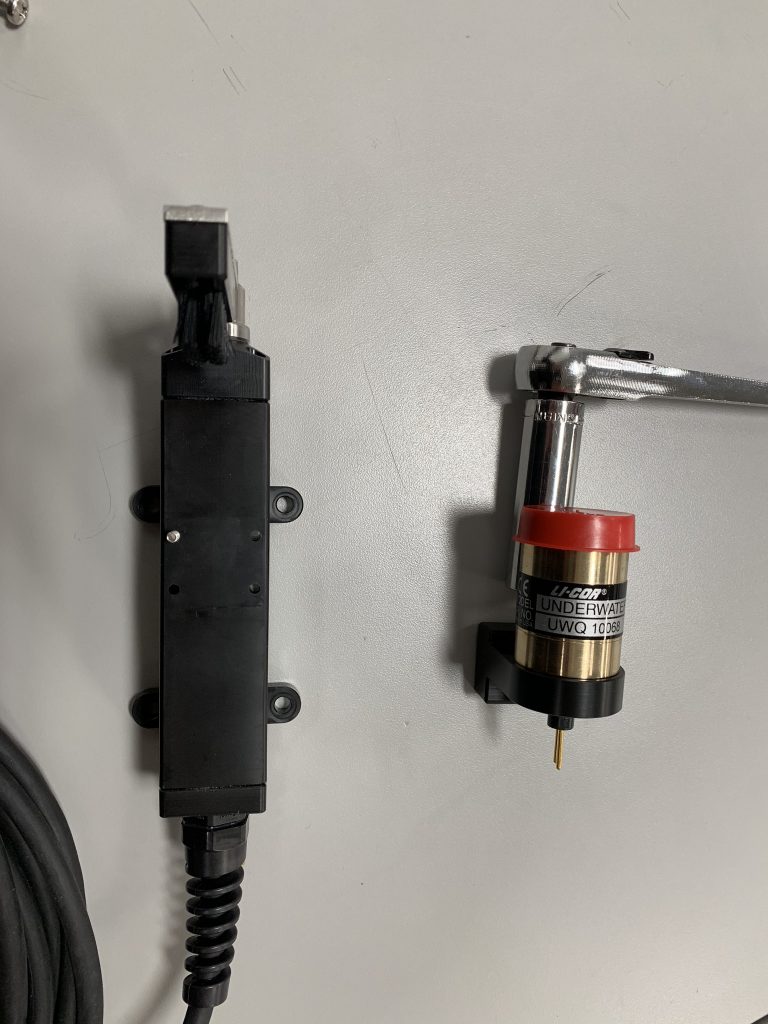

- Connect the LI-COR 192 cable to the sensor.

- Align the exterior dimple of the cable with the yellow mark identified earlier.

- Reversing the cable orientation will not harm the sensor. This will simply cause PAR readings to show negative instead of positive values.

- Press together gently until it fully locks in place. Twist the white cap until hand tight.

- Align the exterior dimple of the cable with the yellow mark identified earlier.

Attach a Standard instrument cage to the Unistrut arm

- Use a 7/16″ socket wrench along with a 7/16″ combination wrench to secure the arm to the cage using the (4) 1/4-20 nylon insert nuts, (2) U-bolts and braces from the “Unistrut Arm to Instrument Cage” bag .

- One of the U-bolt ends will need to pass through one of the circular cutouts on the Unistrut for a proper fit.

- Note the instrument cage orientation prior to securing the unistrut so the PAR sensor faces the desired direction. The cage eye-nut will face downwards during deployment.

Attach a XL instrument cage to the Unistrut arm

- Use a 3/8″ socket wrench along with a 3/8″ combination wrench to secure the arm to the cage using the (2) 3/8-16 X 1-1/4″ hex cap bolts, (4) 3/8″ fender washers, and (2) 3/8″ nylon insert locknuts from the “Unistrut Arm to XL Instrument Cage” bag.

a. The fender washers must be fed through the end of the Unistrut and aligned with the XL cage crossarm’s mounting holes.