YSI ODO RTU Calibration Utility

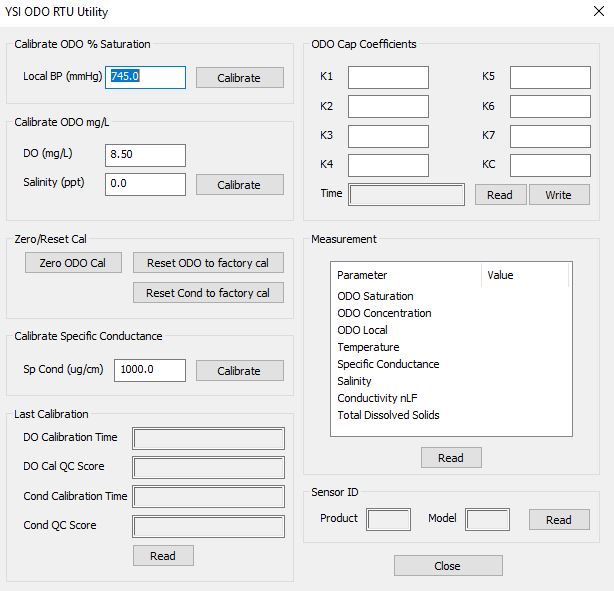

Utilize the YSI ODO RTU calibration utility in CONNECT to enter calibration coefficients, and directly calibrate both dissolved oxygen and conductivity. Calibration coefficients are located on the “YSI ODO Sensor Cap Instruction Sheet” included with the new sensor cap. Once entering the coefficients, the user will need to perform a 1-point DO calibration within the utility. Additionally, before deployment, it is recommended to perform a 1-point conductivity calibration.

Connect Directly to the ODO RTU Sensor

- Download and launch the CONNECT Software.

- Connect the included USB cable between the PC and the YSI ODO RTU sensor.

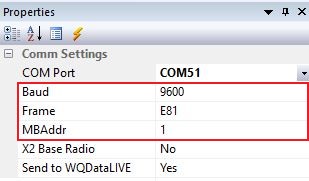

- Locate the Properties window, then select the proper COM Port for the cable from the Comm Settings tab on the far right.

- Set the following:

- Baud = 9600

- Frame = E81

- MBAddr = 1 (Default address is 1; however, enter the appropriate address if it has been changed).

- Set the following:

Figure 1: COM port properties.

- Provide 12VDC power to the YSI ODO RTU sensor.

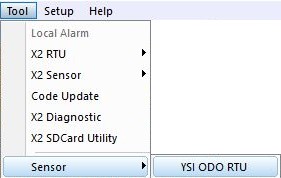

- Go to Tool | Sensor | YSI ODO RTU.

Figure 2: YSI ODO RTU utility location. |  Figure 3: YSI ODO RTU calibration utility. |

Perform Conductivity Calibration

- Reference the Calibration – Conductivity section 3.2 (page 7) in the manual at the following link to properly set up the sensor for calibration.

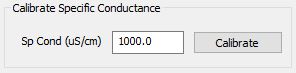

- Select the appropriate calibration standard for the conductivity of the sampling environment.

- Enter this value in the available field, wait for the sensor to stabilize in solution, then click Calibrate .

Figure 4: Insert conductivity standard solution concentration in the available field.

Note: The available options allow for factory reset of all calibrations if necessary.

Insert DO Cap Coefficients and Calibrate DO

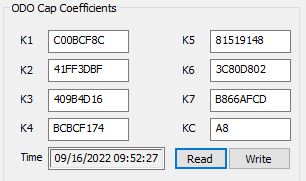

- Using information from the “YSI ODO Sensor Cap Instruction Sheet”, insert the calibration coefficients into the box next to their corresponding ‘K’ values.

- Read the coefficients before writing the new values.

- Double-check all values and then press Send Coefficients.

Figure 5: New ODO cap coefficients.

- YSI recommends performing a 1-point DO calibration once installing a new sensor cap. Follow the Calibration – Dissolved Oxygen section 3.3 (page 8) in the manual link below to properly set up the sensor for calibration.

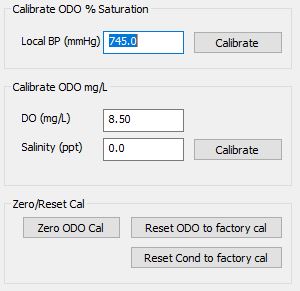

- For dissolved oxygen calibrations:

- If calibrating ODO % saturation, enter the local barometric pressure in mmHg using a 3rd party sensor. Click Calibrate after allowing the sensor to stabilize in solution.

- Note: The barometric pressure by a local weather forecast is sea-level corrected, and thus, cannot be used.

- If calibrating ODO mg/L, enter the known DO standard in mg/L and the known salinity value. Click Calibrate after allowing the sensor to stabilize in solution.

- Note: The calibration ignores the salinity value input if the ODO RTU includes a conductivity sensor.

- If performing a zero standard calibration, click Calibrate after allowing the sensor to stabilize in solution.

- If calibrating ODO % saturation, enter the local barometric pressure in mmHg using a 3rd party sensor. Click Calibrate after allowing the sensor to stabilize in solution.

Figure 6: ODO sensor calibration options.

Note: The available options allow for factory reset of all calibrations if necessary.

Read Last Calibration Time and Live Measurement

Once performing a calibration, the sensor provides the latest calibration time and the QC score. There are three potential responses for the QC score:

- 0 (Best)

- This indicates proper sensor calibration and that all performance-related parameters meet factory-defined limits.

- 1 (OK)

- The sensor is still performing within factory-defined limits. However, during calibration, the required adjustment suggests significant sensor drift potentially requiring further maintenance, such as a new DO cap.

- 2 (Bad)

- The sensor is not performing within factory-specified limits. In some cases, a bad QC Score might indicate that a component of the sensor is due for replacement (such as a DO cap). Exceedance of a user-defined limit is another possibility, for example, an expired term since the most recent calibration.

Note: Once calibrations are complete, it is recommended to read a direct measurement value from the sensor in the standard solutions.