Calibrate a G2-RAIN

The G2-RAIN’s included rain gauge comes factory calibrated. However, to ensure the most accurate measurements this calibration should be verified regularly.

Note: There are two versions of the G2-RAIN, one with a HyQuest Solutions tipping bucket and the other manufactured by Rickly.

Rickly Tipping Bucket | HyQuest Solutions Tipping Bucket |

Rickly Tipping Bucket Calibration

- Remove the siphoning tipping bucket by loosening the three connection bolts and lifting up. Follow the guide below to learn how to remove the siphoning tipping bucket.

- Remove the rain gauge from the G2-RAIN-RTU base by unscrewing the (3) 9/16″ bolts.

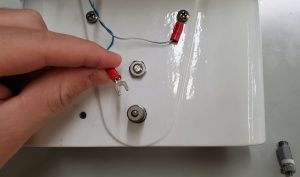

- Remove the tipping bucket leads from the reed switch and the other screw holder.

- Loosen the cable nut and carefully, one at a time, remove each tipping bucket lead through the cable gasket.

- Set the G2-RAIN-RTU aside.

- Loosen the cable nut and carefully, one at a time, remove each tipping bucket lead through the cable gasket.

- Level the gauge using the bulls-eye level

- Move the adjustment screw (under the opposite bucket) all the way counter-clockwise.

- The bucket over that screw should lie flat.

- Move the adjustment screw (under the opposite bucket) all the way counter-clockwise.

- Using a syringe and a mass balance, weigh out the standard amount of water necessary to achieve a tip for the specific tipping bucket model by following the table below.

- While the syringe is empty on the scale, zero the scale to correct for the mass of the syringe, and then add the proper water mass.

- Using a syringe and a mass balance, weigh out the standard amount of water necessary to achieve a tip for the specific tipping bucket model by following the table below.

| Model Number | Grams per Tip (g) |

| G2-RAIN-0.01” | 8.40 |

| G2-RAIN-0.1mm | 3.31 |

| G2-RAIN-0.2mm | 6.62 |

| G2-RAIN-0.5mm | 16.54 |

| G2-RAIN-1.0mm | 33.08 |

- Slowly release water into the raised bucket side.

- Once all of the water has been released, slowly spin the adjustment screw (that was lowered in step 4) clockwise until the bucket tips.

- This adjustment will force the bucket to tip whenever that specific mass of water is pooled into the bucket.

- Once all of the water has been released, slowly spin the adjustment screw (that was lowered in step 4) clockwise until the bucket tips.

- Repeat for the other bucket

- Confirm the calibration by replacing the outer cover and letting a known amount of water flow through the gauge until 5 tips have occurred for each bucket.

- Before beginning the measured test, let several tips occur to ensure the assembly is wet.

- Confirm the calibration by replacing the outer cover and letting a known amount of water flow through the gauge until 5 tips have occurred for each bucket.

- Measure the output from each bucket separately.

Make any necessary changes to the adjustment screws ¼ turn at a time until the expected measurement is achieved

HyQuest Solutions Tipping Bucket Calibration

All HyQuest Solutions gauges are calibrated at the factory; however, HyQuest Solutions does provide products for calibration or calibration checks:

- Field Calibration Device (Model FCD)

- Laboratory Calibration Unit (Model TB340A)

- Recalibration service at HyQuest Solutions’ factory

HyQuest Solutions Tipping Bucket Calibration Check

The HyQuest Solutions Field Calibration Device (FCD) is designed to check tipping bucket calibrations in the field. There are multiple FCD models; however, these FCD’s have all been calibrated to hold a known amount of water, which will be discharged into the tipping bucket, while the user or the data logger records the number of tips.

Follow the Field Calibration Device Manual to perform a calibration check.

- Using the FCD-314 model (314 mL volume), the following table displays the theoretical number of tips that should occur (+/- 1 tip difference) when performing a field calibration check.

- Ensure to know the model of your tipping bucket for proper comparison with values in the table.

| Theoretical Number of Tips | ||

| Bucket Size | 200 mm Catch | 203 mm Catch |

| 0.2 mm | 50.0 | 48.5 |

| 0.5 mm | 20.0 | 19.4 |

| 1.0 mm | 10.0 | 9.7 |

| 0.01 inch | 39.4 | 38.2 |

- Using the FCD-653 model (653 mL volume), the following table displays the theoretical number of tips that should occur (+/- 1 tip difference) when performing a field calibration check.

- Ensure to know the model of your tipping bucket for proper comparison with values in the table.

| Theoretical Number of Tips | ||

| Bucket Size | 200 mm Catch | 203 mm Catch |

| 0.2 mm | 103.9 | 100.9 |

| 0.5 mm | 41.6 | 40.4 |

| 1.0 mm | 20.8 | 20.2 |

| 0.01 inch | 81.8 | 79.4 |

Please contact either NexSens or HyQuest Solutions for further information.